Why Roller Track Conveyors Are Taking Over the Material Handling Industry?

Introduction

Conveyor systems have been around for centuries, and their

use can be traced back to the Roman Empire. In the years since then, there have

been many different types of conveyors invented for a variety of purposes. But

one type of conveyor that is becoming increasingly popular in the material

handling industry is the roller track conveyor.

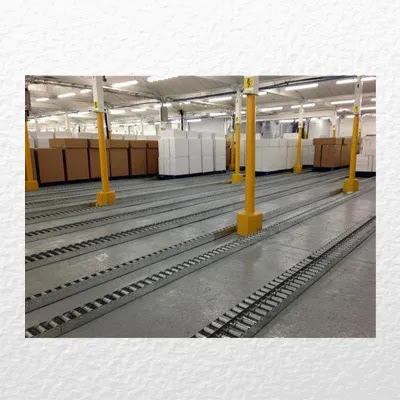

Roller track conveyors are conveyor systems that use rollers

instead of belts to move materials. They are typically used in heavy-duty

industrial applications where load capacity and reliability are paramount.

There are many reasons why roller track conveyors are taking

over the material handling industry. To learn more about this trend, read on!

What are roller track conveyors?

Roller track conveyors are a type of conveyor system that

use rollers to move items along a track. These conveyors can be used for a

variety of applications, such as moving boxes, totes, or pallets. Roller track

conveyors are typically used in warehouses or other industrial settings.

There are a few different types of roller track conveyors,

including chain-driven, belt-driven, and gravity conveyors. Chain-driven roller

track conveyors use a chain to move the rollers, while belt-driven roller track

conveyors use a belt. Gravity conveyors use the force of gravity to move the

rollers.

Roller track conveyors are a versatile and economical way to

move materials around a warehouse or other industrial facility. If you're

considering using a roller track conveyor in your business, contact a material

handling equipment

The benefits of roller track conveyors

Roller track conveyors are an efficient and versatile

material handling solution for a wide variety of industries and applications.

They offer a number of benefits over other types of conveyors, including:

-Improved Efficiency: Roller track conveyors are designed to

minimize friction and maximize efficiency. This results in a system that can

move large volumes of material quickly and smoothly.

-Flexibility: Roller track conveyors can be designed to meet

the specific needs of your application. They can be configured to change

direction, merge, and split loads.

-Safety: Roller track conveyors are a safe option for

material handling. They are designed to keep materials from falling off the

conveyor and to prevent operator injury.

If you are looking for an efficient and versatile material

handling solution, roller track conveyors may be the perfect option for your

needs.

The disadvantages of roller track conveyors

Although they are commonly used in industrial and commercial

settings, there are some disadvantages to using roller track conveyors.

One of the main disadvantages of roller track conveyors is

that they can be noisy. The rollers can create a lot of noise as they move

along the tracks, which can be disruptive to workers in the area. Additionally,

the rollers can also become damaged over time, which can cause them to break

down and need to be replaced.

Another disadvantage of roller track conveyors is that they

can be difficult to clean. The rollers can accumulate dust and debris, which

can be difficult to remove. Additionally, the tracks can also become clogged

with dirt and debris, which can make it difficult for goods and materials to

move along the tracks.

Lastly, roller track conveyors can be difficult to maintain

and repair. The rollers and tracks can experience wear and tear over time,

which requires regular maintenance and occasional repairs. Furthermore, if the

parts are not well maintained, they can become damaged and require more

extensive repairs than usual.

The future of roller track conveyors

Recent advancements in roller track conveyor technology have

made them increasingly popular in a variety of industries. Conveyor systems are

now being used in manufacturing, food and beverage processing, warehousing and

distribution, and more.

What's driving this trend? There are several factors,

including an increase in labor costs, the need for faster and more efficient

production, and the desire to improve safety and ergonomics in the workplace.

Roller track

conveyors offer a number of advantages over traditional conveyor belts,

including higher speeds, lower maintenance costs, and improved safety. As technology continues to evolve, we can expect to see even more uses for roller

track conveyors in the future.

So, if you are now going to search for Roller

Track Manufacturers then

go for The Phoenix Industry.

Comments

Post a Comment