Why Roller Track Conveyors Are Taking Over the Material Handling Industry?

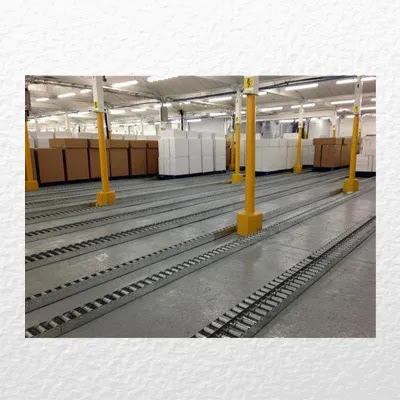

Introduction Conveyor systems have been around for centuries, and their use can be traced back to the Roman Empire. In the years since then, there have been many different types of conveyors invented for a variety of purposes. But one type of conveyor that is becoming increasingly popular in the material handling industry is the roller track conveyor. Roller track conveyors are conveyor systems that use rollers instead of belts to move materials. They are typically used in heavy-duty industrial applications where load capacity and reliability are paramount. There are many reasons why roller track conveyors are taking over the material handling industry. To learn more about this trend, read on! What are roller track conveyors? Roller track conveyors are a type of conveyor system that use rollers to move items along a track. These conveyors can be used for a variety of applications, such as moving boxes, totes, or pallets. Roller track conveyors are typically use...